Episode 86: Wood is Good: Thermally Modified Wood with Chris Bouchard

Ted speaks with Chris Bouchard at BPWood in Penticton, British Columbia. BPwood is a family run lumber company that specializes in being Nimble Innovators.

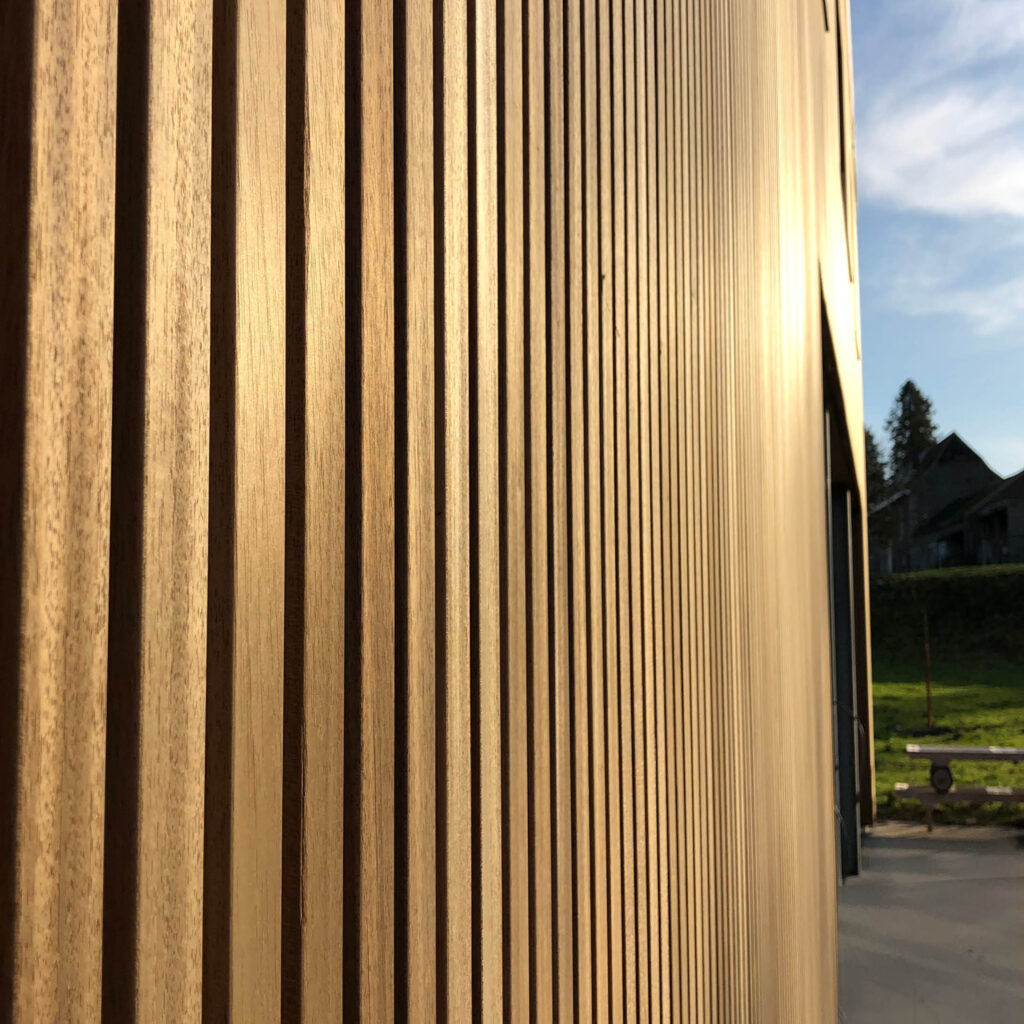

Today Ted unravels the greenwashing of composite materials vs. new wood products. While most consumers and builders are looking for durable outdoor materials like red cedar, BPWood has been revolutionizing the global lumber supply chain by introducing a new product called ThermoWood. This thermally modified wood is more sustainable and cheaper than other alternatives and today you’ll hear where it comes from, how it’s made, and all the different ways it can be used to change the industry.

TOPICS DISCUSSED

- [2:12] How extreme sports translates to the family business

- [6:28] Why did you join the family business?

- [9:00] What’s the difference between regional woods?

- [10:45] Hardwood vs. softwoods and sustainability

- [14:45] Thermally Modified Wood: what is it and how is it made?

- [18:50] Reclaimed lumber and its durability

- [21:20] What’s your biggest challenge? Education?

- [24:20]What’s the application of it?

- [28:10] Thermowood is great for harsh climates

- [29:00] What makes BPWood stand out from the competition?

- [30:45] Do woods cycle, not just in popularity but in supply?

- [33:25] The stories wood can tell

- [34:30] BPWood products

- [37:00] What changes have been made in the company over the years?

- [40:05] Where do you see BPWood 5 years from now?

- [40:55] What markets do you excel in?

- [42:42] What’s the price point?

- [43:45] Is there pressure on the composite industry?

- [47:05] Current projects

KEY QUOTES FROM EPISODE

- Thermo Wood is a, well the thermal modification of wood is a process that has been studied in Europe from the early 1900s and the whole idea is to use heat and water to take a piece of traditionally non-durable wood and make it durable. Europeans don’t grow, they don’t have Western Red Cedar. Western Red Cedar is naturally known as the most naturally resistant or durable wood for exterior cladding and fencing and railing and decking and things like that. So the Europeans had to come up with a solution to take the material that they can grow in their forests and make durable wood products.

- I think the vision for the company is to get a little bit deeper into markets that we’ve historically done good business in. We built the company on being a very wide company, and that’s got us a long way. We understand the world. We know how things move around the world. We have a very global understanding of softwood. And my focus for the company is to see us dig a little deeper into those individual lanes. And just increase business that way. I believe you can only be so good at a lot of things and you can become masters at a few things that will make you stickier in the marketplace.

- The broader message for all of these home building groups is that wood is good. Wood has a better carbon footprint and a more sustainable story than any hardy board ever created, than any composite deck ever created. We need to reintroduce wood as being good. That’s my message to the whole industry, not just the high end home guys.

About

BP Wood

From the first cut of the log to the final user, BPWood delivers sustainable supply chains on the periphery of pure commodity wood product markets. Working with manufacturers, importers and distributors, we trade wood products globally.

You may also like

Episode 106: Strategies For Long-Term Success with Christian Nickum of Rocky Mountain Hardware

Ted speaks with Christian Nickum, president of Rocky Mountain Hardware, discussing the journey of ta

Episode 65: Grow Your Business Through Simplification with Brandon Nicastro, of GCS Glass

Today Ted speaks with Brandon Nicastro, owner and CEO of GCS Glass in Phoenix, Arizona. Founded in 2

Modern Eclectic Interior Design: A Love For Beautiful Things with Nida Risto | Friends of Build Magazine #82

Ted speaks with Nida Risto, founder of Nida Risto Interiors, a Wyoming-based interior design firm on